The ceramic capacitor is made by making a finely grounded powder of a dielectric material which is either paraelectric material like the titanium.

What are ceramic capacitors made of.

It is broadly classified into three basic classes.

Technical article x7r x5r c0g.

Change in temperature voltage and frequency.

Types of ceramic capacitor.

Ceramic powder is mixed with binder and solvents to create the slurry this makes it easy to process the material.

They are not polarized which means that they may be safely connected to an ac source.

As is pointed out in the article ceramic composition and properties perovskite ceramics have a face centred cubic fcc crystal structure.

Ceramic capacitors are also very small in size and have a low maximum rated voltage.

A concise guide to ceramic capacitor types march 30 2018 by robert keim this technical brief attempts to dispel some of the fog that surrounds the three character cryptograms used to describe ceramic caps.

The capacitors in which the ceramic material such a paralectric titanium oxide or ferroelectic is used as the insulating material or dielectric is known as the ceramic capacitors.

Most ceramic capacitor dielectrics are made of barium titanate batio 3 and related perovskite compounds.

Ceramic capacitors are classified as type i type ii or type iii.

The type i ceramic capacitor generally has a dielectric made from a mixture of metal oxides and titanates.

If you ve ever wondered about how ceramic chip capacitors mlccs are made check out this page from johnson dielectrics.

This class of ceramic capacitors provide more stability in capacitance value w r t.

The lower is the type of class the superior it is in terms of performance.

Ceramic capacitors are usually made with very small capacitance values typically between 1nf and 1µf although values up to 100µf are possible.

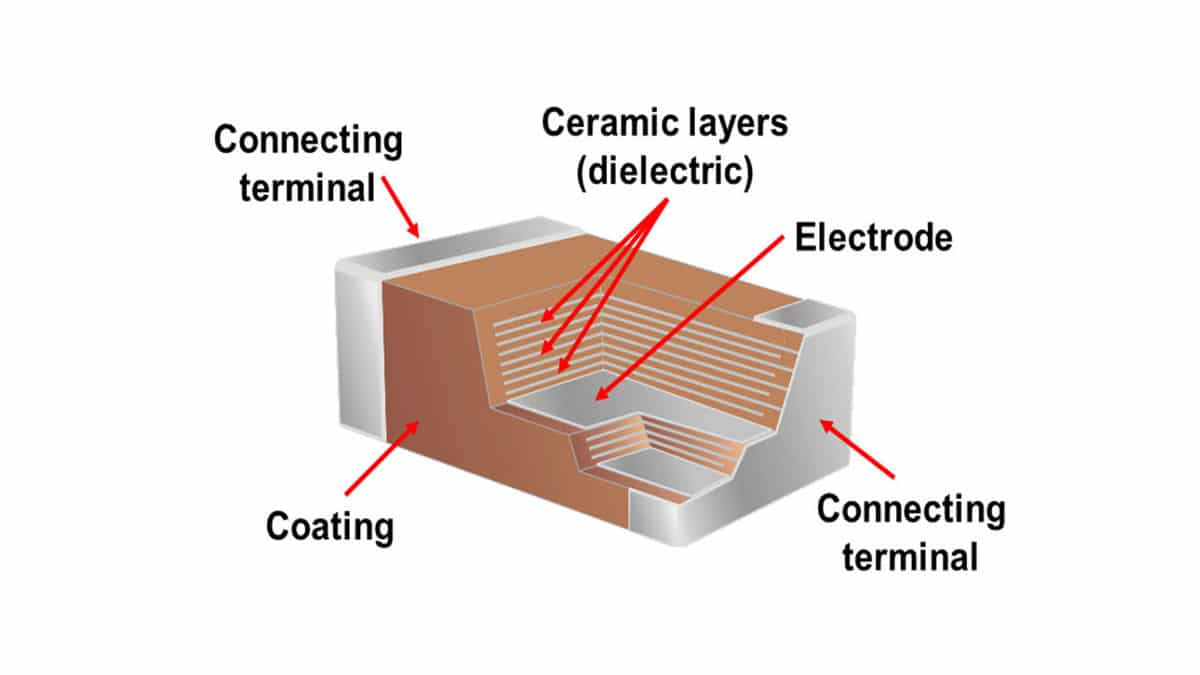

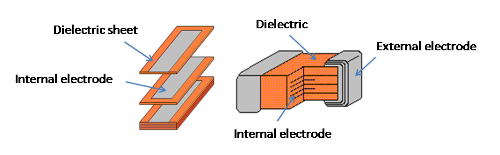

A ceramic capacitor is a fixed value capacitor where the ceramic material acts as the dielectric it is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes the composition of the ceramic material defines the electrical behavior and therefore applications.

They have high insulation resistance and lower frequency losses and maintain a stable capacity even when voltage varies.

The process of making ceramic capacitors involves many steps.

These are used in resonant circuits filters and.