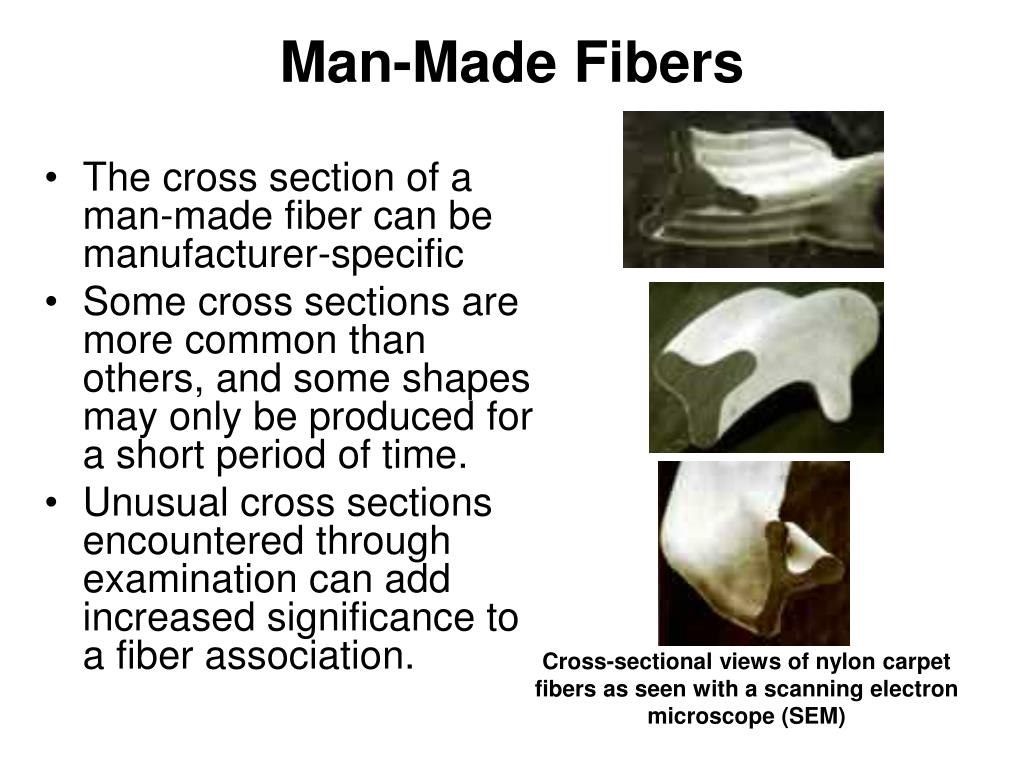

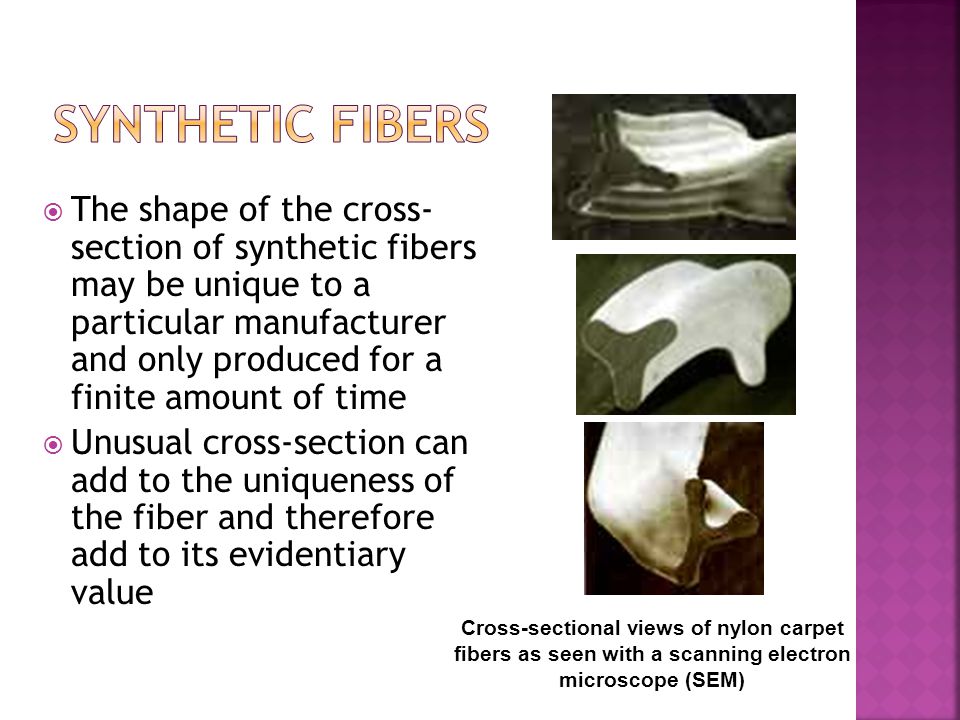

Some cross sections are more common than others and some shapes may only be produced for a short period of time.

What cross sectional shape do most carpet fibers have.

4 6 production and early processing.

Which cross section below is most often used to create silk like manufactured fibers.

Fiber shape affects luster body or space texture and hand you can control natural fiber s cross section.

4 8 processing of ramie fiber.

The cross sectional shape of the metal fibers with small diameters 25 75 μm is round while the shape is a crescent for fibers with large diameters.

A metal rod is inserted into a glass tube and then passed.

3 2 the polymer system of cotton.

In this process liquid glass has a high viscosity and can be made easily into fibers as follows.

Other natural fibers are more often made into area rugs including sisal cotton seagrass jute silk and coir.

All fibers had a trilobal cross sectional shape.

True or false false cross section cannot be controlled.

For each fiber type examined a minimum of three diameter values were measured and recorded.

Nylon carpet is usually moderately priced not quite as expensive as wool but more expensive than polypropylene and polyester.

The method of measurement differed depending on the observed cross section of the fiber.

Nylon carpet of midlevel and higher quality can last up to 12 to.

3 1 the cellulosic fibers.

Most of these fibers are either too weak or too rough to be made into broadloom.

Increases of yarn twist carpet face weight and carpet pile height accompanied an increase in the carpet quality.

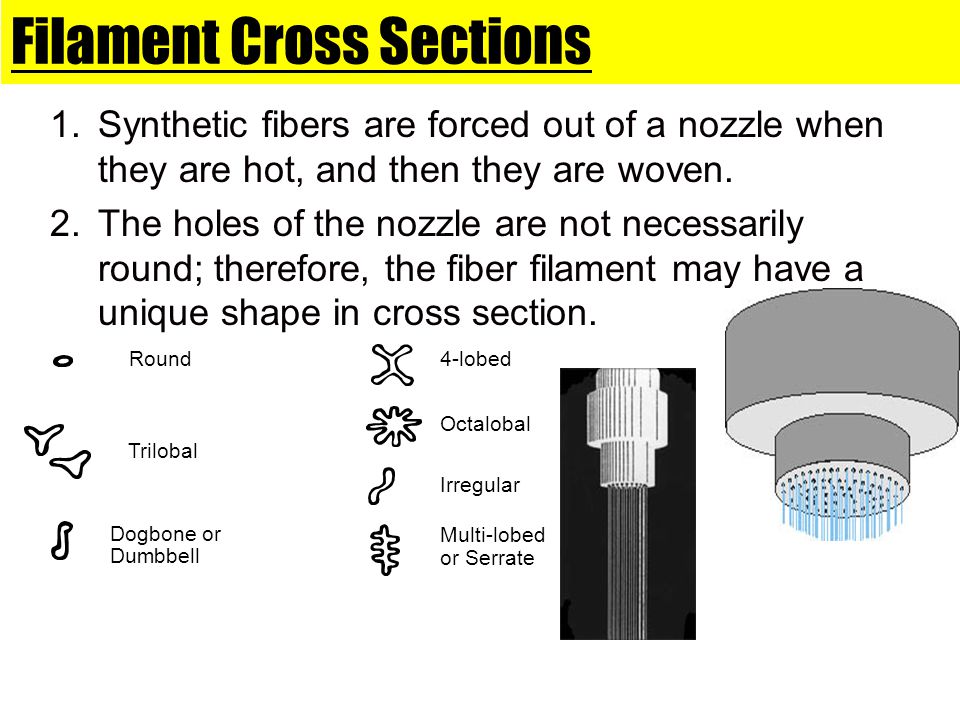

Staple and continuous filament fiber spun staple fiber synthetic spun fibers are first extruded which occurs when synthetic fibers like nylon begin as pellets and are then melted into hair like filaments.

Unusual cross sections encountered through examination can add increased significance to a fiber association.

However it had no obvious effects on contact angles on individual fibers.

Wool is by far the most common natural fiber in carpeting and is virtually the only natural fiber used in broadloom wall to wall carpet.

Yarns with metallic components are not considered novelty yarns.

These filaments are then heated cooled and crimped to improve strength and impart other physical characteristics.

Heavy striations were also recorded.

All of which makes it the most popular carpet fiber by far 90 for homes and heavily favored 65 for all uses both residential and commercial.

Second the lowest weight carpet had much larger fibers than the other two carpets.

4 2 fibre composition and morphology.

The cross section of a man made fiber can be manufacturer specific.

4 4 conversion of fibre to products.